Trend in Construction Design during and after the Pandemic

The impact of Covid 19 to our daily lives and surroundings will long affect each and everyone of us and decisions that we will make from now on. As the saying goes “ Prevention is better than the Cure “. The construction market and trends in choosing the materials use in our walls, ceilings, buildings and houses are more important now more than ever. For too long we have lived, worked, played, stayed in environments built to minimum considerations to safety, human health and environmental impact. It’s time for a change.

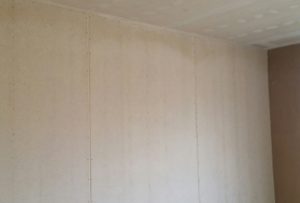

TRILITE RMS board – a new age, fire & water resistant, noncombustible, multi-purpose board that is virtually impervious and keeps out insects, termites, rodent infestation. Our boards does not feed molds and mildew, is non-toxic, non-flammable and noncombustible. It is seldom we find such advantages in a single building board compare to traditional materials . These qualities are most relevant now in keeping us safe, healthy and comfortable in the air we breathe.

TRILITE RMS boards – produce from inert natural minerals mainly magnesium oxide powder, magnesium as we know is also use as a supplemental vitamin . It is also a major ingredient in antacids and laxatives. The benefits when taken orally is numerous, the same way as a major raw material in our boards, there is surely no harm to human health.

During the pandemic times, cleaning and sanitizing is very important to keep virus and germs out. Choosing a board that does not deteriorate when expose to water from spraying disinfectants is important too. If constantly expose to moisture , wood based boards may disintegrate, constant moist may harbor insects, rodents, etc… that is not what we want to happen.

TRILITE RMS boards – tested in Finland and classified as “ M1” – the safest indoor climate environment building product ranking. 100% free from carcinogens, ammonia, asbestos, formaldehyde, TVOC, VOC. Non-hazardous and sensory evaluated.

We have a choice, we hope that our numerous advantages will not be dismiss. T he decision to choose TRILITE RMS boards now is a long term investment to the health and safety of our lives, our loved ones and the people around us

With the idea to save time, labor , overall cost, on-site delays due to unpredictable weather conditions, the idea to pre-built at factories and just deliver on site had been an increasing importance and trend in the construction industry. Our MgO based high strength TRILITE RMS flooring is one of the choice material to use over plywood, cement board, strand board or particle board due to its :

With the idea to save time, labor , overall cost, on-site delays due to unpredictable weather conditions, the idea to pre-built at factories and just deliver on site had been an increasing importance and trend in the construction industry. Our MgO based high strength TRILITE RMS flooring is one of the choice material to use over plywood, cement board, strand board or particle board due to its :