Products

- Fireproof , Green Construction

- Silica free and Chloride ion free

- Will not rot or decay in humid environment

- Resistant to termites, mold, fungus, mildew and insects

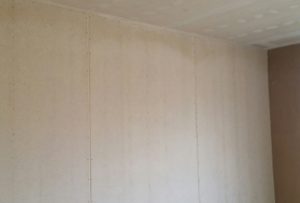

Application Areas of RMS Board

- In combination with insulation materials such as EPS, XPS, Polyurethane foam, Rockwool, Glasswool, Fiberglass for superior sound, heat and fire insulation of partition walls and sandwich panels. Ideal for pre- fabricated light steel buildings and constructions.

- For areas where you need the best water and moisture protection.

- For furniture and decoration manufacturing (fireproof doors, counters, cabinets, safe deposits boxes, etc…)

- For all interiors and exterior kinds of facings, linings, ceilings, raised flooring, underlayment, render backing among all others.

- For all applications needing the best heat, fire, termite, mold, mildew protection.

Easy to Finish

RMS Board smooth side is ready to take all kinds of wall finishing such as paint, textures, stucco, render coatings, wallpapers. Rough back side is ideal for wall adhesives to stick with tiles, granites, and other lamination materials.

Safe to Use

RMS Board is an inert product qualifies for use in hyper-allergenic and clean room applications. It is non-toxic, free from any kinds of materials hazardous to human health or to the environment. It has been certified as class M1 safe product in Finland.

Easy Installation

RMS Board is engineered for strength, can be use for all forms of construction from wooden frame, metal frame and SIP panel assemblies. Easily cut with circular or reciprocating saws. It can be installed using nails, screws or staples.

Dimension

| Thickness | 3mm upto 20mm |

|---|---|

| Standard Width | 1000mm / 1200mm / 1220mm |

| Standard Length | 2440mm / 2700mm / 3000mm |

Key Benefits

- Excellent dimensional stability

- Excellent bond strength

- Severe duty rated for impact

- Euroclass A1 rated for reaction to fire

- Easy to handle and cut on site.

- Vapour permeable

- Weather resistant – will not delaminate or bow

- High pull-out strength – screw fix or nail

- Mould and mildew resistant

- Verified low embodied carbon

- 100% non hazardous material

- Superb moisture, fire and thermal resistant board.

Physical & Mechanical Properties

| Test Properties | Test Standard | Test Result | Unit |

|---|---|---|---|

| Bending Strength | BS EN 310 | 12.1 ~ 17.1 | N / mm2 |

| Compressive Strength | BS EN 12390-3 | 8.3 | N / mm2 |

| Modulus of Elasticity | BS EN 310 | 5210 ~ 7845 | N / mm2 |

| Impact resistance | BS 5669 : Part 1 | 23 | mm / mm |

| Screw Withdrawal strength | BS EN 320 | 69 ~ 87 | N / mm2 |

| Racking Strength | EN 14358 | 9mm = 7.52 12mm = 8.41 | kN (on 0kN load per stud) |

| Racking Strength | EN 14358 | 9mm = 12.09 12mm = 16.98 | kN (on 5kN load per stud) |

| Thermal Conductivity | EN 12664 | 0.21 | W/mK |

Water & Moisture Resistance Properties

| Test Properties | Test Standard | Test Result | Unit |

|---|---|---|---|

| Water Vapour Transmission | BS EN ISO 12572 | 48.1 | g / m2 . Day |

| Swelling in Thickness after immersion in water | BS EN 317 | 0.2 | % |

| Cyclic Test in Humid Condition | BS EN 321 | -0.1% | Ave. thickness swelling to 3 cycles of immersion in water for 72 hrs, freezing at -12°C to 20°C for 24 hrs, Drying at 70°C for 72 hrs. |

| Movement from dry to saturated state | CNS 13778 | 0.3 | % |

| Moisture Absorption Rate | CNS 13778 | 35 | % |

| Length expansion after water absorption | CNS 13778 | 0.06 | % |

| Porosity | GB/T 7019-2014 | 33.4 | % |

TRILITE® RMS Board was tested by renowned Swedish SP laboratory for its hygroscopic moisture movement in comparision with 2 other MgO boards in 12mm thickness. The boards were conditioned in a climate chamber with a temperature of 20°C and 95% RH ( relative humidity). Visual finding results : After 42 days, no water was release or seen for the TRILITE RMS boards, while reference MgO sample#1 from factory A , started releasing water after 12 days, and MgO sample#2 from factory B started releasing water after 2 days.

Durability

| Test Properties | Test Standard | Test Result | Unit |

|---|---|---|---|

| Water Impermeability | EN 12467 | Category A | No signs of water penetration after 24 hours, NO dampness or dripping on the undersides of the board. |

| Heat Rain Incorporating Thermal Shock from water spray (50 cycles) | EN 12467 | Category A | No bowing, warping, cracking, or delamination occurred. No deterioration in their water impermeability performance after the test showing neither traces of moisuture nor water drop formation |

| Freeze-Thaw (100 cycles) | EN 12467 | Category A , post Freeze- Thaw MOR = 12.9 MpA | There was no visual damage noted on completion of the 100 cycles |

| Soak / Dry (50 cycles) | EN 12467 | Category A, post soak/dry MOR = 13.5 MpA | There was no visual damage noted on completion of the 50 cycles |

| Bending Strength after 24 hours soak in water | EN 12467 | Category A, MOR = 15.3 MpA | Classified as a Class 4, Category A board |

TRILITE® RMS Board fulfill the requirements of the highest durability category “A” according to EN 12467 and may be subjected to heat, high moisture and sever frost.

100% Safe, Non-Toxic and Non-Harmful to Human Health

| Test Properties | Test Standard | Test Result | Unit |

|---|---|---|---|

| Fungi Resistance | ASTM C-1338 | Fungal Resistant – No growth | Biosan Lab – USA |

| Alkalinity | BS 6829 | Sodium Oxide : 56.7% ( ph between 9.5 – 10 ) | TUV Sud – Singapore |

| Asbestos Content | NIOSH 9002 | No Asbestos Content | TUV Sud – Singapore |

| Sulphide S2 content | BS EN 196-2 | No Sulphide S2 Content | TUV Sud – Singapore |

| Formaldehyde Content | ISO 14184-1 | No Formaldehyde Content | TUV Sud – Singapore |

| Evaluation of Toxic Fumes generated during burning | BS 6853 | 100% Non-toxic below the IDLH value of listed gases, summation index R, is less than 0.3 | TUV Sud – Singapore |

Fire Rating and Fire Resistance Performance

| Test Properties | Test Standard | Test Result | Unit |

|---|---|---|---|

| European Fire & Building Classification Standard | EN 13501-1 | A1 or A1fl | A1 = Europe’s highest fire classification, BRE tested |

| Surface Burning Characteristic to USA Standard | ASTM E-84 | Class “A” | NGC – USA tested |

| Flame Spread | ASTM E-84 | 0 | NGC – USA tested |

| Smoke Developed | ASTM E-84 | 0 | NGC – USA tested |

| Fire Rating – 9mm thickness boards | BS 476 Part 22 | 71 minutes | Exova Warrington – UK |

| Fire Rating – 12mm thickness with steel & timber support | BS 476 Part 20 | 132 minutes (Steel) 123 minutes (Timber) |

CERAM – UK |

| Fire Rating – 12mm Single Specimen | BS 476 Part 20 | 180 minutes | CERAM – UK |

| Combustibility | EN 1182 and BS 476 Part 4 | Non-combustible | Warrington Tested |

| Bomb Calorimeter Test (Gross heat of combustion) | BS EN ISO 1716 | Below 0.606 MJ/kg | BRE- UK Tested |

| Surface Spread of Flame | BS 476 Part 7 | Class 1 | Warrington Tested |

Sound Insulation Performance

| Test Properties | Test Standard | Test Result | Unit |

|---|---|---|---|

| 12mm TRILITE® RMS partition wall | BS EN ISO 717-1 | Rw = 48 | dB |

| 12mm TRILITE® RMS partition wall | BS EN ISO 717-1 | Rw = 45 | dB |

Dimensional Tolerances

| Test Properties | Test Standard | Test Result |

|---|---|---|

| Density | Kg / m3 | 1080 (± 150) |

| Length & Width | mm | – 2mm, + 3mm |

| Straightness of Edges | mm | < 2mm |

| Squareness of the boards | mm | < 5mm |

CE Marking Conformity Number : 14SH200005029 according to European Construction Products Regulation (No. 305/2011).

Sanding Options

- Sanded on 1 side / Smooth surface on the other side.

- Sanded on 2 sides.

- “A1” fire grade material & non-combustible

- Strict thickness Precision, minimum deviation

- Unaffected by water & moisture, does not degrade nor deteriorate when in contact with water.

- Very safe, does not contain asbestos, formaldehyde or any other toxic substances

- Ideal for fire doors, flooring, walls, substrate for lamination, furnitures, countertops, others

- Easy to cut, glue, fix, install & decorate

| Density | 1080 Kg /m3 (±150) |

|---|---|

| Bending Strength | 12-17N/mm2 |

| Compressive Strength | 8.3 N/mm2 |

| Modulus of Elasticity | 7845 N/mm2 (Gmm) |

| Thermal Conductivity | 0.21 W/mK |

| Thickness Swelling(wet) | 0.2% |

| Dry-Saturated Movement | 0.3% |

| Length (wet) | 0.06% |

| Water Vapour Transmission | 48.1 g/m2.day |

| Moisture Content | 12.5 % (weight) ±10% |

| Surface Alkalinity | 9.5 pH |

| Fire Resistance Classification | A1 | EN 13501-1 |

|---|---|---|

| Noncombustibility | Noncombustible | EN ISO 1182 |

| Surface Spread of Flame | Class 1 | BS 476 part 7 |

| Surface Burning | Class A | ASTM E-84 |

| Flame Spread | Zero | ASTM E-84 |

| Smoke Develop | Zero | ASTM E-84 |

| Gross Heat Combustion | 0.606 MJ/kg | EN ISO 1716 |

| Toxic fumes generated when burning | 100% non-toxic | BS6853 |

| Asbestos Content | 100% No Asbestos | NIOSH 9002 |

| Formaldehyde Content | 100% Free | ISO 14184-1 |

| Fungi Resistane | 100% No Growth | ASTM C-1338 |

TRILITE® RMS PREMIUM is a 100% inorganic board manufactured without any wood fibre, adding more of fire resistant perlite in our core structure of MgO + MgSO4 composition.

The board will perform better as it will absorb less moisture, increase resistance to fire and gives unparalleled dimensional stability, and as a bonus, lighter in weight.

Suitable for a wide range of external, internal and broader range of special applications for your building board requirements.

- Ceiling

- Interior Wall

- Exterior Wall

- Partition Wall

- Floor Underlayer

TRILITE® RMS flooring are produce from high quality raw materials that are environmentally friendly, safe, noncombustible, moisture resistant and sustainable. It can be fix to timber or steel joists.

- Withstand various climactic conditions

- No harmful or toxic chemicals in our composition

- Termite, mould, mildew and fungus resistant

- Resistant to flooding and prolonged water immersion

- Quick, easy to install and fix with no special tools required.

Technical Specifications

| Density | 1250 kg/m2 ±10% |

|---|---|

| Moisture Content | ≤14% |

| Moisture Absorption rate | ≤16% |

| Dry Shrinkage rate | 0.5% |

| Wet Bulking rate | 0.6% |

| Impact Resistance | ≧2.0 KJ/m2 |

| Screw Grip Force | 15 N/mm2 |

| Noncombustibility | Class A1** |

Board Tolerances

| 15mm ~ 20mm thickness | ±1.0mm |

|---|---|

| Length | ±2mm |

| Width | ±2mm |

| Squareness | ≤5mm |

NEO BOARD is a unique multipurpose general construction board, developed with cost effectiveness in mind. The surface are produce without slurry , hence small pinholes are visible on board surface. It is produce from a proven mixture of consistent raw materials , i.e : MgO powder, MgSO4, perlite, wood fibre, and others embedded with layers of middle alkali leno weave glass fiber mesh . It is a water resistant board, subjected to 100 cycles of freeze thaw test, 50 cycles of soak-dry and heat-rain incorporating thermal shock. It is 100% asbestos free, formaldehyde free, non-toxic, fungus& mildew resistant and stable.

| Application areas |

|

|---|

Dimensions

| Thickness | 1220 x 2440mm, 1220 x 2700mm, 1220 x 3000mm |

|---|---|

| Size | 3mm up to 18mm |

* Custom sizes or thickness upon request *

- Mould Resistant

- Water Resistant

- Does not break easily

- Easy to cut, fix and install

- Chloride free- no salt leaching

- Fireproof, Noncombustible

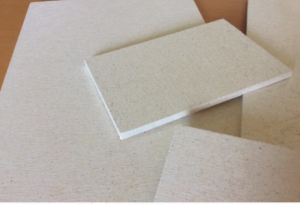

Neo Surface

NEO Backside

Neo Core

Technical Data

| No. | SPECIFICATION | TEST STANDARD | TECHNICAL VALUE (Unit) |

|---|---|---|---|

| 1 | Density | EN 12467 | 1100 kg/m3 ( ± 10% kg/m3, thickness dependent) |

| 2 | Noncombustible & Fire Resistant Properties | EN ISO 1182 | Fully – Noncombustible |

| EN ISO 13501 – 1 | CLASS A1 | ||

| EN ISO 1716 | 2.2141 MJ/Kg (Gross Heat Release) | ||

| 3 | Thermal Conductivity | EN 12664 | 0.210 W/mK |

| 4 | Water Vapor Permeability | BS EN ISO 7783 | 1.35 MNs/g |

| 5 | Water Absorption Rate | JC 646 | ≤ 20 % |

| 6 | Moisture Content | JC 646 | ≤ 14 % |

| 7 | Dry Shrinking Rate | GB/T 7019:2014 | ≤0.3% |

| 8 | Wet Bulking Factor | GB/T 7019: 2014 | ≤0.5% |

| 9 | Screw Grip Force | JC 688 | ≧ 20 N/mm |

| 10 | Length & Width Tolerance | EN 12467 | ≤ ± 5mm |

| Thickness Tolerance | ≤ ± 10% | ||

| Straightness of Edge | 0.15% | ||

| Squareness of Edge | ≤ 5 mm | ||

| 11 | Water Impermeability | EN 12467 | No drop formulation , Category A |

| 12 | Category, class | EN 12467 | Category A , Class 1 , Level 1 |

| 13 | Warm Water Resistance Heat / Rain Resistance Freeze / Thaw Resistance Soak / Dry Resistance | EN 12467 | PASS |

| 14 | Racking Resistance | BS EN 594 | 1.85 kN/m (no vertical load) 2.24 kN/m (5 kN/m applied load) |

| 15 | Fungus & Mold Resistance | ASTM C-1338 | 100% Free from Fungus & Mold Growth |

| 16 | Determination of Asbestos | NIOSH 9002 | Asbestos Content – NOT DETECTED |

| 17 | Formaldehyde Content check | ISO 14184-1 | Formaldehyde Content – NOT DETECTED |

| 18 | Effect of Acid & Alkali | Resistant – No Change | |

| 19 | Biological Resistance to insects, rodents, termite | Highly Resistant & Unaffected |