FAQs

1. What’s difference with TRILITE RMS and other MgO boards producers?

- RMS boards are produce from reinforce fibrous materials in combination with our unique formulation of chloride free mixture, combination of high purity magnesium oxide , magnesium sulfate, perlite, others... The chemical composition is proven, stable, technically performing soundly.

- Unlike MgO boards, RMS will not leach any salt or chemicals over time, it will not corrode screws and steel structures, it’s stronger and you can see the difference by immersing both MgO & RMS in water for months, after taking both board out at same test duration. MgO boards with no force breaks easily, while RMS board is harder to break . RMS is breathable and vapour permeable compare to other MgO boards.

- A study was commissioned in Sweden for comparing the hygroscopic moisture absorption between MgO and and RMS boards. From 2-12 days, other MgO boards started to release, while after 42 days RMS boards still shows no tendency to release water.

2. What surface materials can be applied on the TRILITE boards ?

As external cladding - it is important to seal with waterproof coating before applying final paint/coating for external. Anticipated movements within the structure should be followed for the design of the façade. Stainless steel screws or corrosion treated.

As tile backer - in wet applications and humid areas such as bathrooms, kitchens and utility rooms. TRILITE is suitable to install behind shower walls and floors, with surface covered with ceramic tiles. Boards should be seal before the tiles are installed.

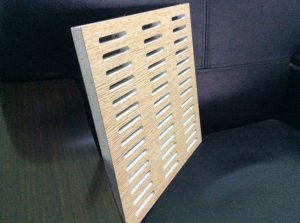

As Decorative substrate – can be glued and laminated with most types of surface decoration materials, i.: HPL , Melamine, real wood veneer, bamboo, acp, mdf, aluminum foils , etc...

Our boards can be rendered with acrylic, lime, silicone, polymer modified, mineral based and solvent based renders. Painted with compatible coating ( test with paint suppliers ). Surface can also take stone cladding, thin natural cut marbles, tiles, among other cladding materials.

3. What is thickest and thinnest board available ?

We can produce thinnest boards in 3mm and thickest standard board in 20mm. However for special qty and requirements, we had supplied up to 30mm to our clients .

4. Does your factory offer special cut to size boards ?

Yes, we have the cutting facility to offer boards in 600mm width and varying length request from customers. Our longest length production is 3000mm.